EXPLANATION OF SCHEDULED MODES PARALLEL, PER PIECE, AND SPLIT.

Dates in Cetec ERP are defined as follows:

- Parallel - allows as many orders as Num Parallel Segments to be scheduled at a time at this location (capacity minutes permitting.)

- Per Piece - allows orders with qty greater than 1 to schedule one piece at a location for single piece flow scheduling. ‘Num Parallel Segments’, when used with Per Piece, dictates how many pieces can be scheduled at a time. (setup time on the scheduled operation applies to the first unit only).

- Split - divides the labor time by the ‘Num of Parallel’ segments and only permits 1 order to be scheduled at a time. Outsource locations ignore this field.

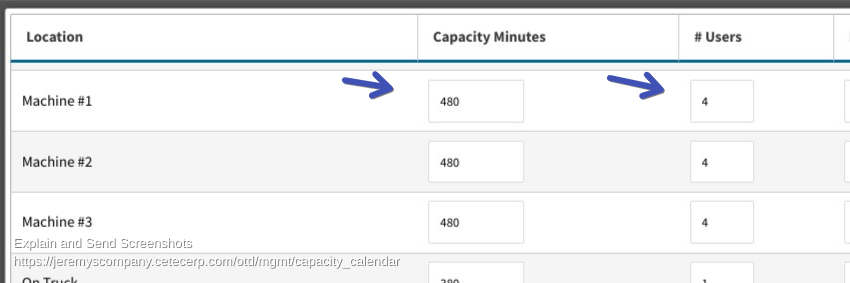

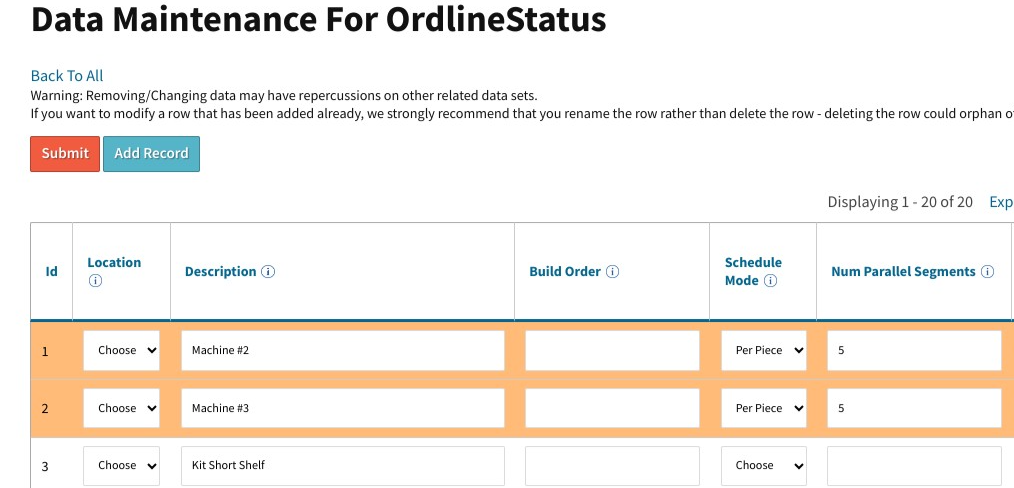

To allow parallel work segments at a location, let’s navigate to the OrdlineStatus data maintenance table. This is located under the Admin module > Maintenance > Data Maintenance > OrdlineStatus. For an example we will use location Machine #1, set the schedule mode to Parallel and set the Num Parallel Segments field to 4. It is also important to ensure there is sufficient capacity set for this location to the right of the page.

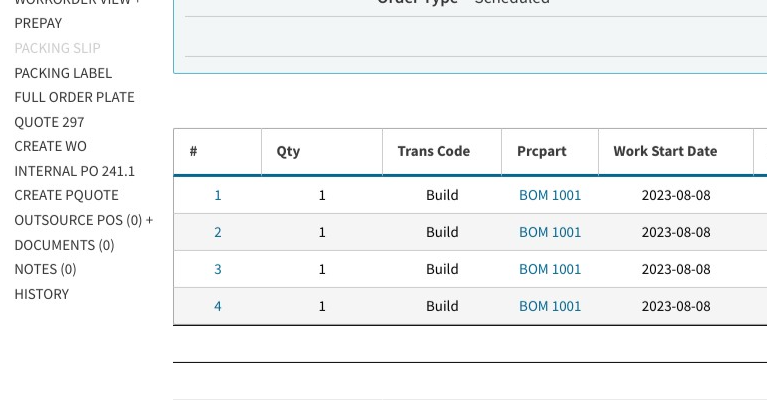

Now that we have our parallel schedule mode and num parallel segments set, let’s look at scheduling production lines for BOM 1001. In the below image there are 4 lines with a work start date of 8/8/2023.

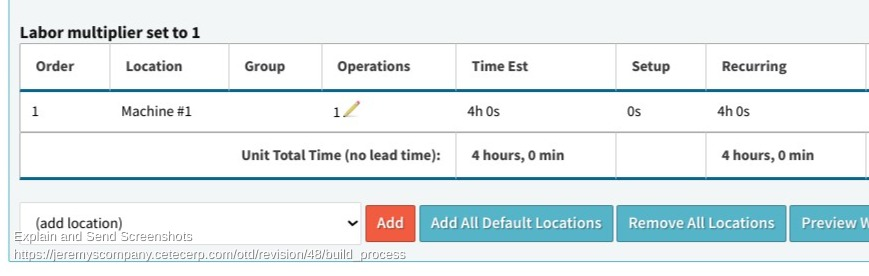

For simplicity, the Labor Plan for BOM 1001 has a single operation at Machine #1 that is estimated to take 4 hours.

Before scheduling our lines lets navigate to Production > Scheduling > Set Capacity to ensure the location has adequate Capacity Mins and # Users are set on the Capacity Calendar for the work start date of 8/8/2023.

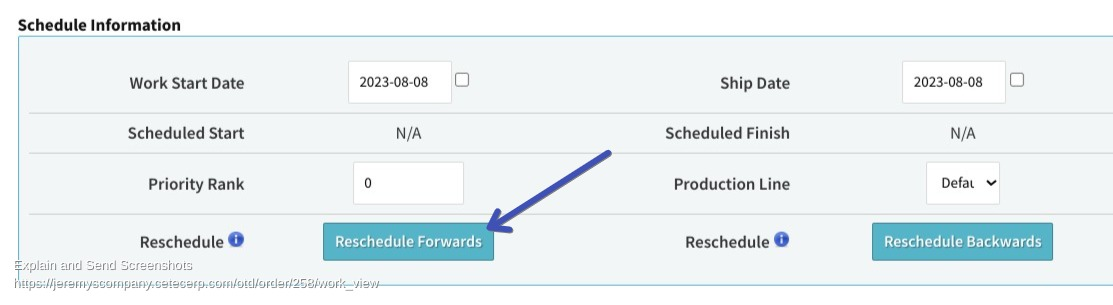

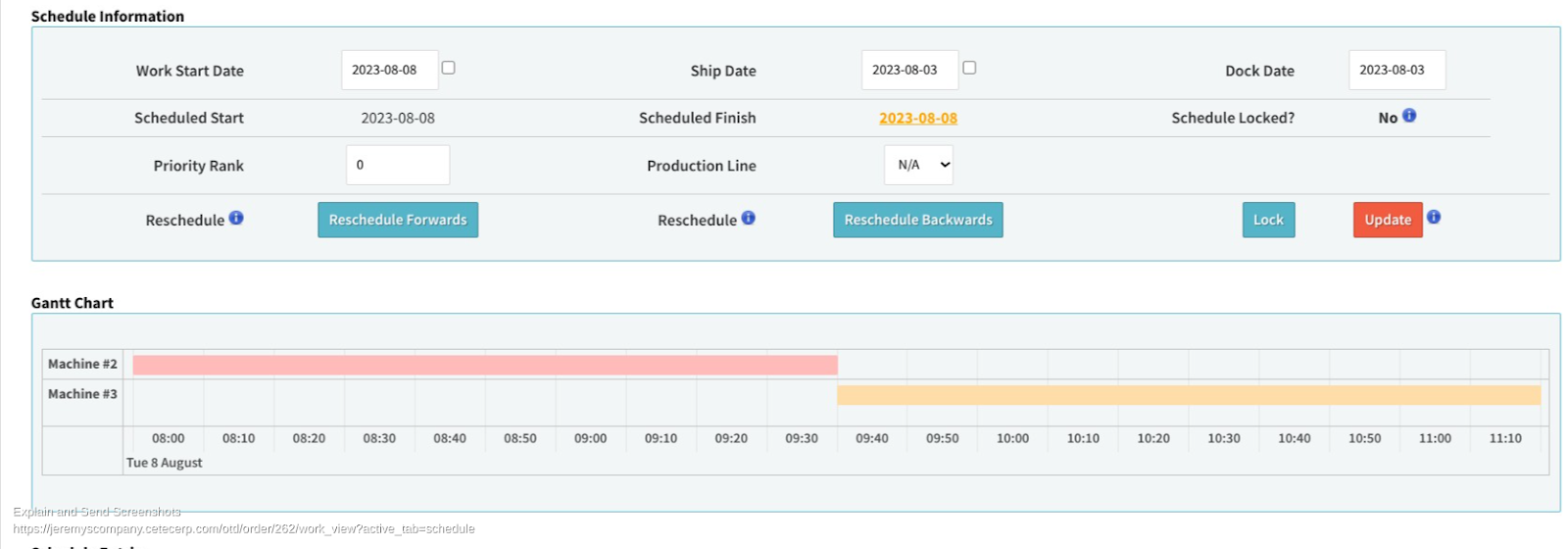

After confirming capacity is available we can now schedule our production lines. On the work order screen for each line, click the Reschedule Forwards or Reschedule Backwards button from within the Schedule tab.

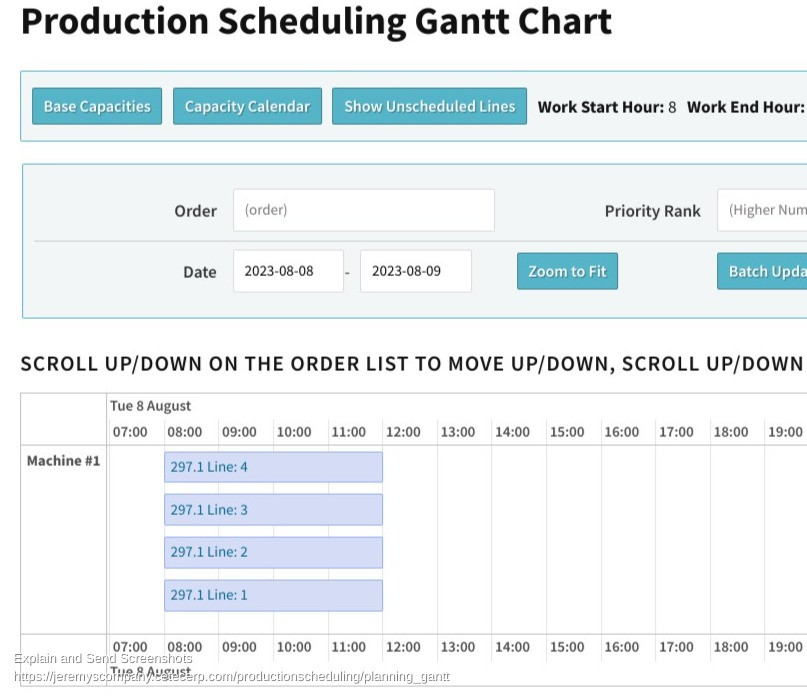

After scheduling all lines on the order, if we navigate to the Scheduling Gantt Chart and view by location for this date we can see that all lines have been scheduled in parallel on August 8th.

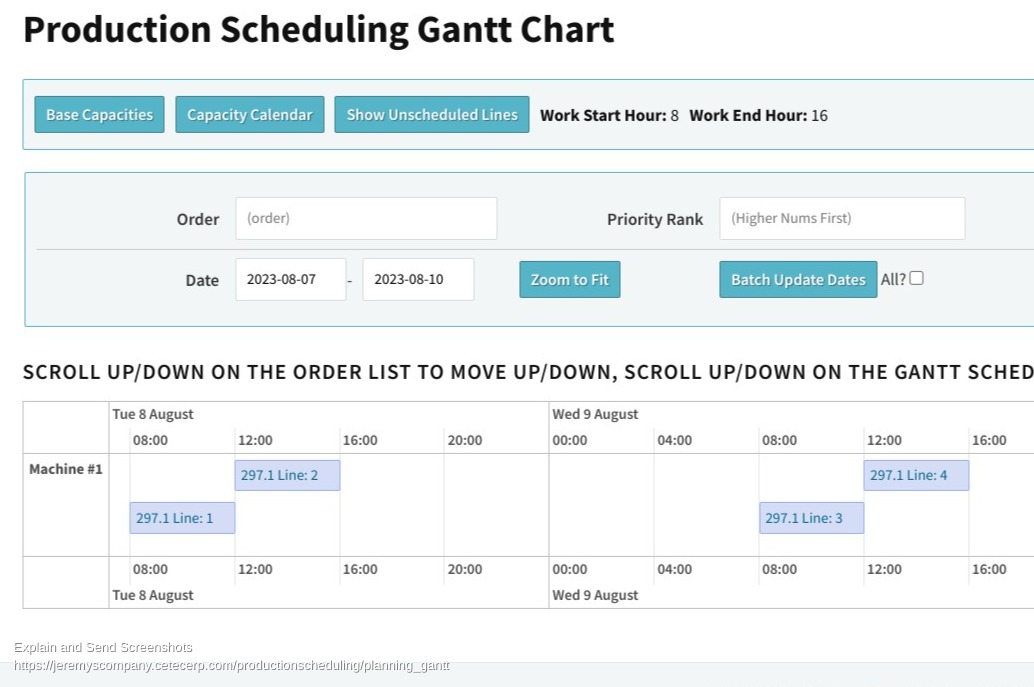

As a comparison, the below image shows the same order lines if they were NOT scheduled in parallel. Notice each line is taking four hours to complete filling up two days worth of capacity whereas the image above shows each line being worked in the same four hour segment from 8:00 am to 12:00 pm.

Scenario: A machine shop has an order with a quantity of 100 for BOM 1002. A single piece will be worked on one machine (machine #2) and immediately move to another (machine #3.) Rather than working all 100 pieces at location Machine #2 and then working working all 100 pieces at Machine #3, the Per Piece scheduled mode can be utilized to schedule single pieces at Machine #2 and then to Machine #3.

Note: Since two (or more) ordlines will be working at the same time it may be useful to status the order at the first location until all pieces are completed, then move to the next location until all pieces are completed, etc.

To set this up the Schedule Mode column on the OrdlinesStatus data maintenance table needs to be set to Per Piece for locations Machine #2 and Machine #3 and have sufficient capacity. For this scenario we will leave the Num Parallel Segments field blank.

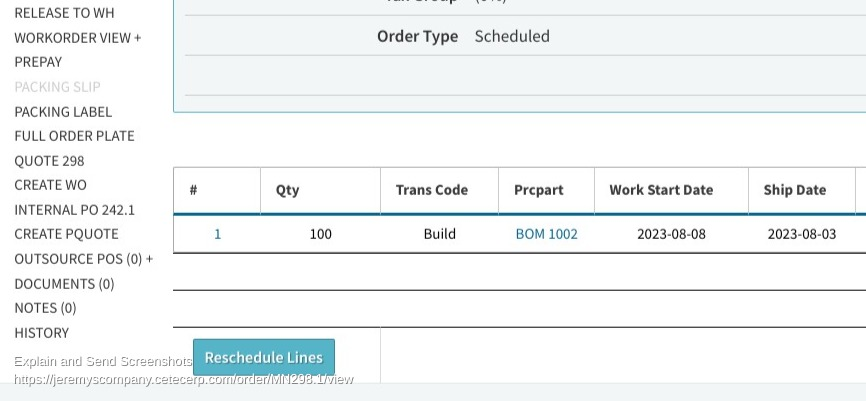

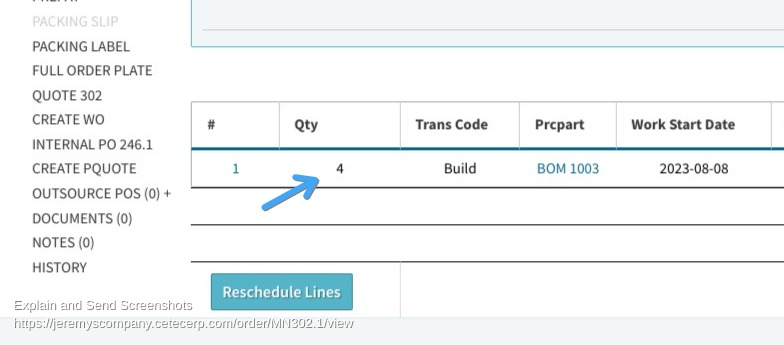

Now let’s look at the below order for a single line building BOM 1002 with a work start date of 8/8/2023.

Part BOM 1002 has a labor plan with two locations, Machine #1 with an operation of 1 min and Machine #2 with an operation of 1 min.

When this line is scheduled we can see individual pieces being worked on one machine and moving to the next. Both Machine #2 and Machine #3 are being worked simultaneously!

Notice the difference! The below screenshot shows the same order scheduled, but not per piece. This order is scheduled from 8:00 am and finishes at 11:20, almost twice as long.

What if you want to work more pieces at a time, but utilize the same scheduling method? This is where the Num Parallel Segments can be used with the Per Piece mode. Say you set the segments to 5, then 5 pieces will be worked at Machine #2 and then move to Machine #3. While the first group of 5 pieces are then being worked at Machine #3 the next set of 5 pieces will start at Machine #2 simultaneously. This would repeat in segments of 5 until all 100 pieces are worked through both locations in the labor plan.

Scenario: A metal shop has a job in which 2 welder’s can work at the same time. They want to divide the work between the two welder’s so that the job takes half the time.

To set this up we will choose ‘Split’ as the scheduled mode and enter ‘2’ in the Num Parallel Segments field for the Welding work location on the OrdlineStatus data maintenance table.

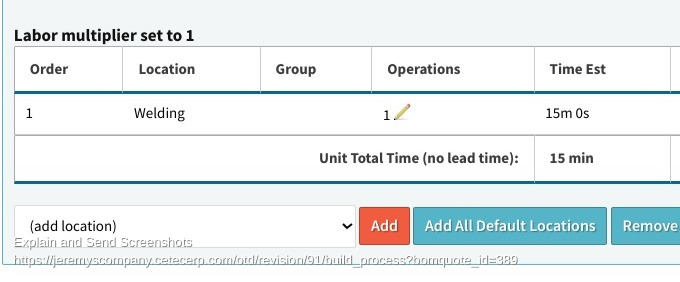

As an example, part BOM 1003 has a labor plan with a single operation for the Welding location. This operation is estimated to take 15 mins for a qty of 1.

In the below order we are building BOM 1003 for a qty of 4. If each qty takes 15 minutes to build we can expect this order to take 1 hour (if scheduled normally).

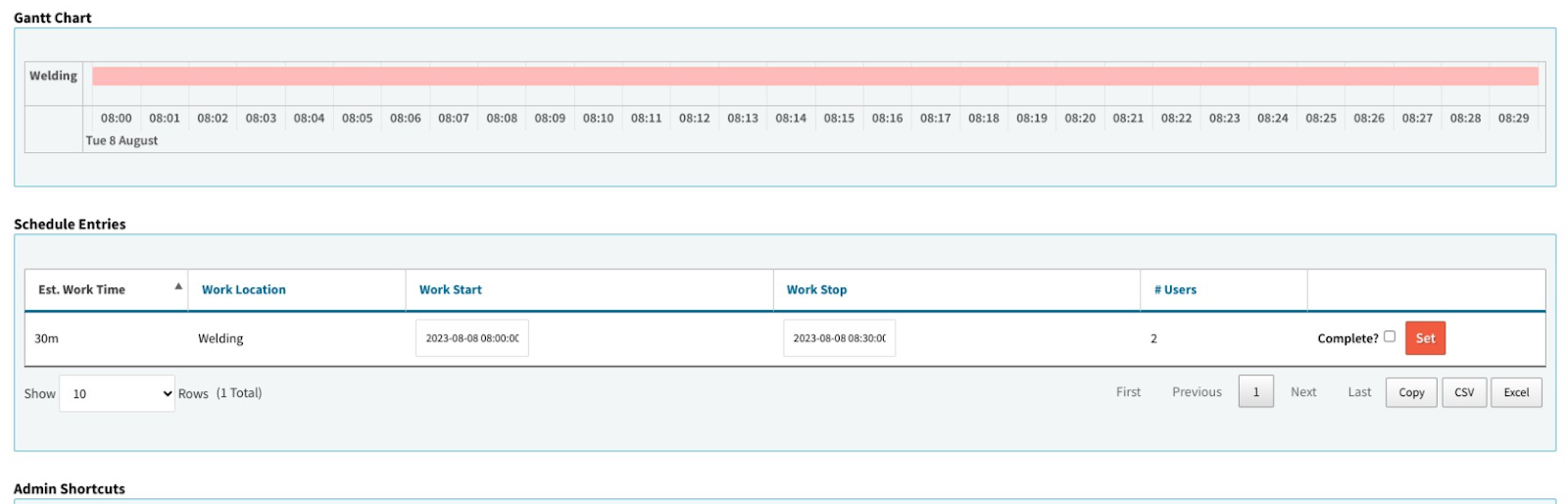

After rescheduling this order forward/backwards this order is scheduled to take 30 mins from 8:00 am to 8:30 am. In the Schedule Entries section we can see 30 minutes estimated and being worked on by 2 users. Using the Split schedule mode, the anticipated hour of work for this job has been divided by 2 users so that only 30 minutes of capacity is consumed for this work location.