Standard Costing In Cetec ERP

Standard costs function like a planned or expected cost, and can also be referred to as a ‘benchmark cost’ or target cost. It’s one of the core cost accounting functions in manufacturing, and critical for manufacturing ERPs to support and automate. It is useful in stabilizing your costs over time, and for measuring PPV (price point variance), which is a typical performance metric for a purchasing team and manufacturing company looking to control cost - which means every manufacturing company!

In Cetec ERP, you can either manage standard costs and variances from an operational standpoint, with operational budgets and reports, or you can function with a true standard cost approach for your Cost of Sales (COS) and inventory by automating the standard cost variances posting to the ledger.

First, let’s look at how Cetec manages the Standard Costing methodology, where the PPV (price point variance) is actually posted to a variance account in the ledger, and the inventory is valued at the standard cost.

Before we dive into the operational reporting, and setting up Standard Costs, there are a few configuration settings to turn on:

- GL - Break Out Std Cost

- GL - Break Out Std Cost at Receipt

These two configs will enable the GL Transaction Mappings to post Std Cost Variances at receipt and at invoice. This automatically posts raw material discrepancies at purchase and labor variances (for build to stock processes and subassemblies) in the manufacturing process to your inventory. Posting the Std Cost variance at invoice ensures that discrepancy now hits your Cost of Goods Sold (COGS) variance account.

How is Standard Costing calculated and what drives the data in Cetec ERP?

Standard Cost is typically calculated and set yearly by the purchasing team. Each company should have its own standard of when Standard Costs are updated, but at minimum you should be analyzing the pricing trend of components over the last year. This can be done by looking at the PO Cost History report. You can then import standard costs back into Cetec, or manually set them on the part records. If you never set a Standard Cost for your parts, Cetec will update to the last buy cost.

Once you know how and when you’re updating Standard Costs, you need to know how you’re valuing your inventory. Are you using standard costing, or are you simply measuring and managing your buyers according to standard costs? Find out by looking for a price point variance (PPV) as a key performance indicator (KPI).

Now let’s move on to setting the Standard Cost, and running operational reports.

Standard costs are warehouse specific and can be edited via the pencil icon found in each warehouse specific data subsection of the part record. They can also be updated in bulk using the Pricing/Cost import feature.

The import feature can be found by going into the Parts module, clicking the Pricing Maintenance dropdown menu, and finally selecting Pricing/Costing Import. You can upload a xlsx or CSV spreadsheet formatted file with the column headers PRCPART, Std Cost, and Location.

The difference between your standard cost & what you purchase the prcpart from the vendor is known as the PPV (Purchase Price Variance).

Setting a standard cost for your parts allows you to compare the ‘benchmark’ cost that you set using standard cost against the cost you actually paid for those parts when purchasing them. This formula provides you with your PPV.

There is a specific report for this process called the Part Standard Cost History report. Users can pull this report to pull all the Standard Costs that have been set, change those to what is desired, and make that change with a simple click.

There are multiple departments that have the ability to see Standard Cost for your parts in Cetec ERP, allowing your teams to coordinate with each other.

Your sales team can run the Invoice Standard Cost History report to pull a list of variances for your parts at the time of invoice. This includes the Standard Cost, the Cost at which that part was invoiced, and the delta between the two. This can be found under the Invoices dropdown on the Sales tab, by selecting “Std Cost History” from the dropdown menu.

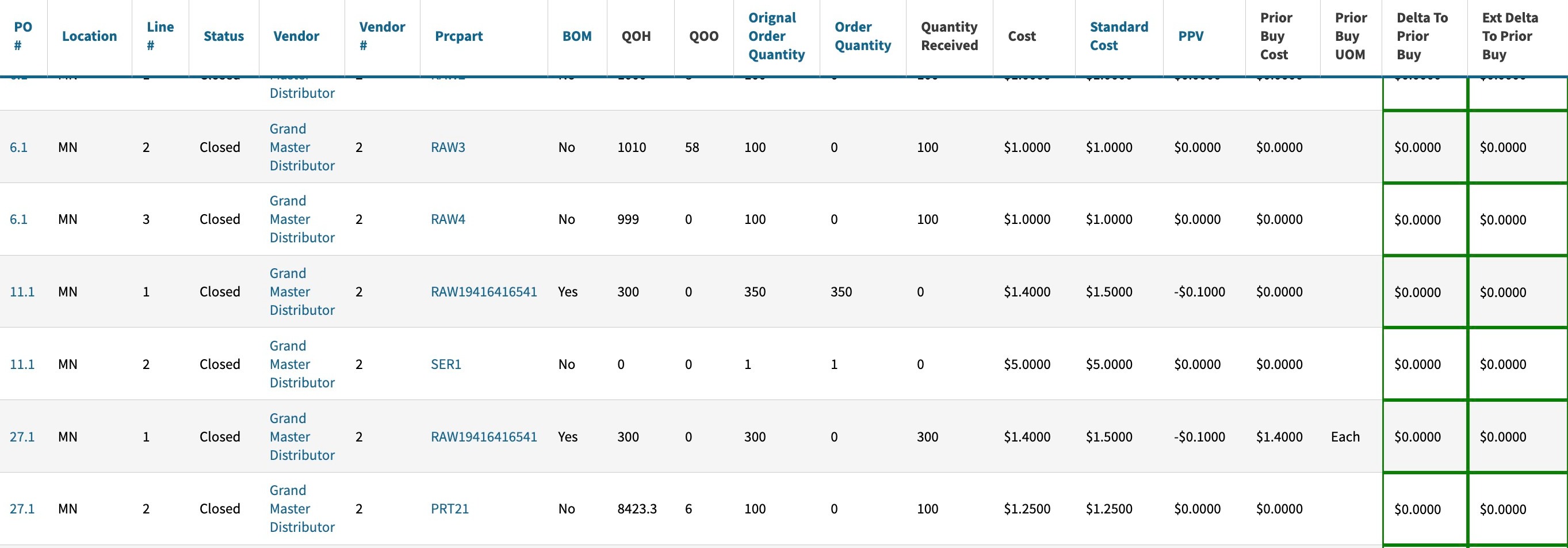

Your purchasing team can also view the Standard Cost for the parts that they purchase by using the PO Cost History report, and compare the Standard Cost column on the report to the PPV column on the report to compare pricing at the time of purchase. The Sales and Purchasing department can then coordinate with the users who manage inventory to ‘set’ those standard costs on the part record by editing the warehouse specific data using the pencil icon.

If you’re ready to implement ‘Standard Cost’ into your part records, check out our detailed guide.