Using Production Status to Enhance Communication on Workorders in Cetec ERP

In manufacturing, seamless communication between team members is crucial to keeping your production processes running smoothly. Cetec ERP’s Production Status feature, available within work orders, is designed to do just that.

Cetec ERP’s Production Status feature provides real-time insights and notes on the status of workorders. It allows users to track the progress of production jobs from start to finish, ensuring that everyone involved in the process is on the same page, and any questions or comments along the way can be addressed. By updating and monitoring production statuses, teams can quickly identify bottlenecks, address issues, and keep projects on track.

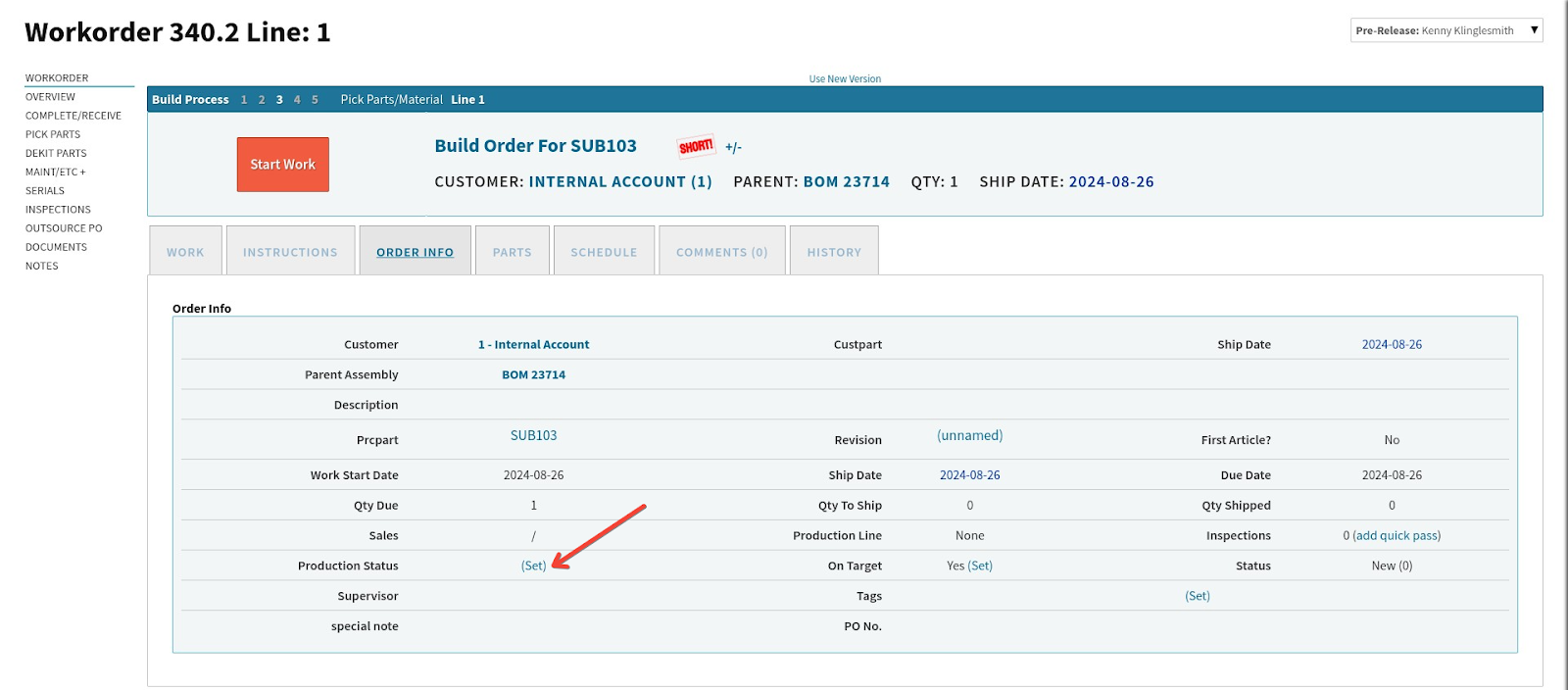

Production Status can be applied to a Workorder within the Order Info tab.

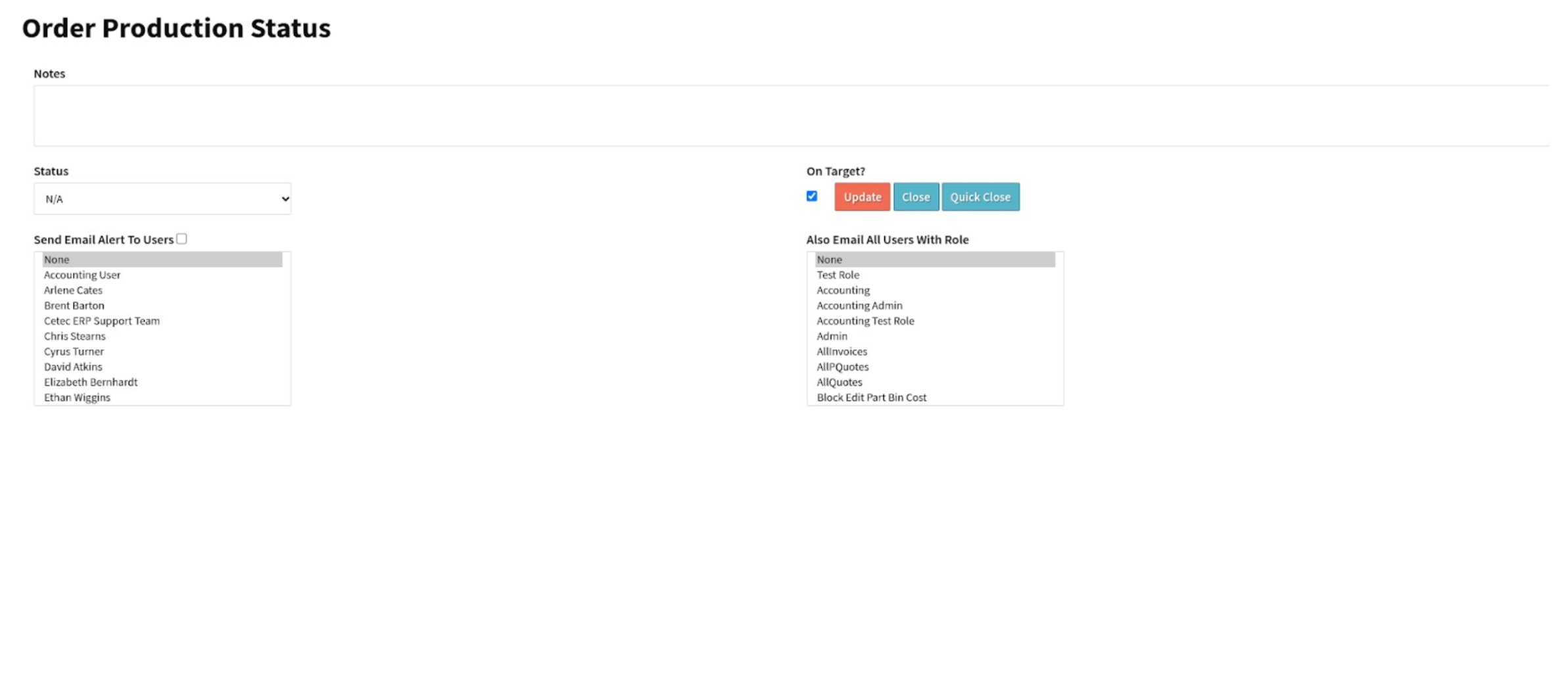

Upon selecting ‘Set’, the Order Production Status module will populate where the applicable status can be set, where any notes related to the status can be added, and where email alerts (including any added notes) can be sent to specific users or user roles to address certain parties and increase necessary visibility into a work order.

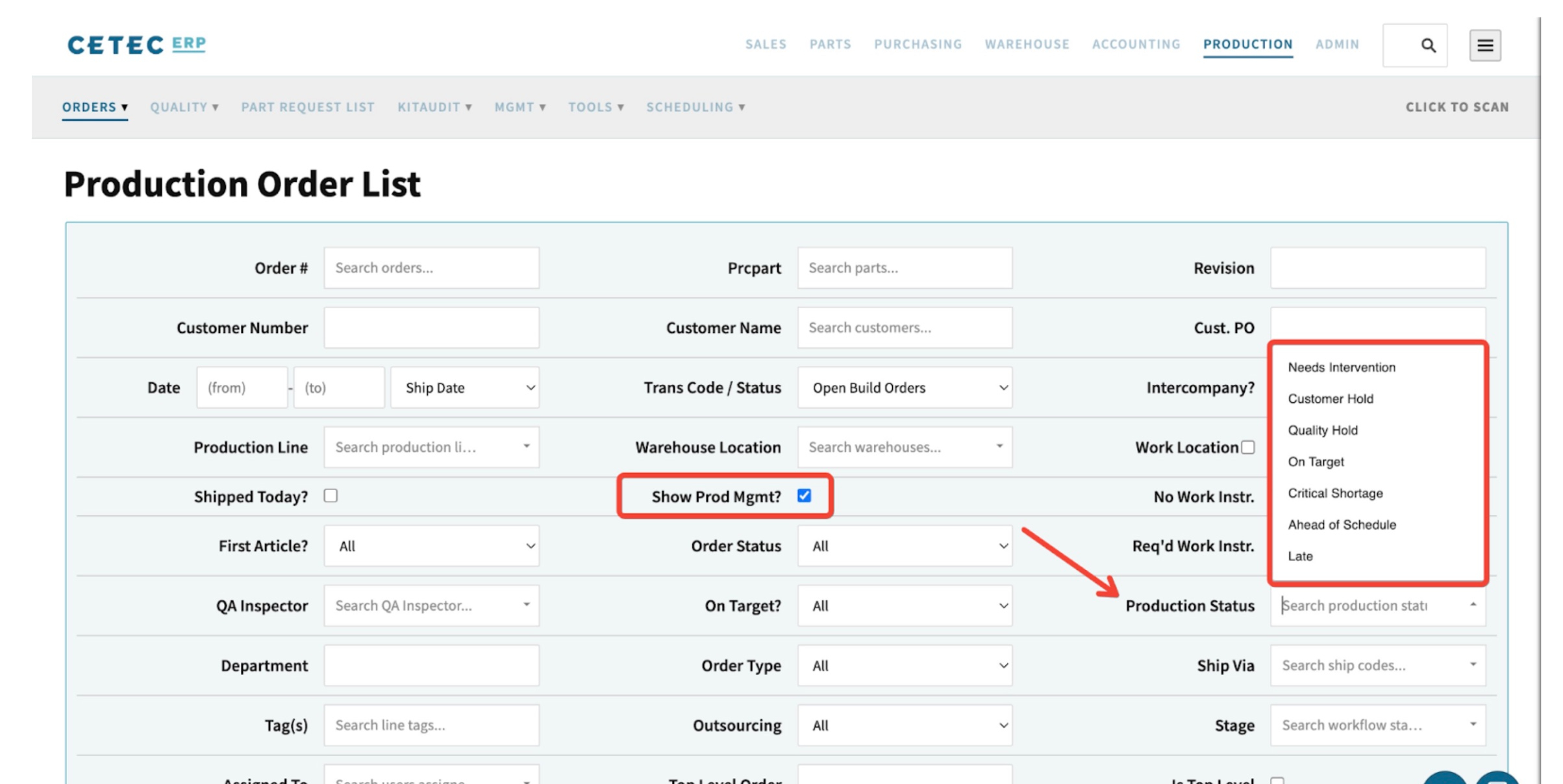

Production status can then be tracked and reported on within the Production Order List report. To reveal it, check the “Show Prod Mgmt” selection. A report column of all production status notes for a specific work order can also be included in this report.

Why Communication Matters in Manufacturing

Effective communication in manufacturing is not just about sharing information—it’s about sharing the right information at the right time. Inaccurate or delayed communication can lead to costly errors, production delays, and inefficient use of resources. Here’s how Production Status in Cetec ERP can bridge these communication gaps:

1) Real-Time Updates

Production Status provides real-time updates on the progress of manufacturing orders to necessary users or user groups. By regularly updating the status of a job—such as “Ahead of Schedule,” “On Target,” or “Late”—team members can instantly see where each job stands. This visibility helps everyone involved to coordinate their efforts more effectively, reducing the chances of misunderstandings and missed deadlines.

2) Centralized Information

Instead of relying on scattered emails or phone calls, taking users out of the system, Cetec ERP centralizes production status information in one accessible location. This centralized approach ensures that all team members, from floor workers to managers, have access to the same shared information and can provide comments or questions via the production status notes tool. Users and user groups selected on a production status will be given email updates when production status and the notes field is updated. Note information is retained as well, serving as a running record of questions, answers, and comments on a workorder.

3) Enhanced Collaboration

By monitoring production statuses, teams can proactively address potential problems before they escalate. For example, if a job status shows “Late”, the team can quickly investigate the cause of the delay and take corrective action. By utilizing the notes section to alert a certain user group of a question or issue, this simplifies the process of addressing any issues or delays that may arise. This proactive approach minimizes downtime and keeps production on schedule with one central location for status communication.

To get the most out of the Production Status feature in Cetec ERP, consider the following best practices:

- Regular Updates: Encourage team members to update the status of work orders regularly. This ensures that the information remains accurate and up-to-date.

- Clear Definitions: Establish clear definitions for each production status to avoid confusion. Ensure that everyone understands what each status means and when it should be used.

- Using Notes Effectively: Emphasize the importance of the notes section to be able to serve as a communication tool to ask questions and make comments on the status of a work order. Highlight that these notes will directly notify the user or user groups selected via email to ensure that questions on an order from the shop floor are not missed.

Implementing these practices will not only improve communication but also contribute to a more organized and responsive team.

Effective communication is the backbone of a successful manufacturing operation. By leveraging the Production Status feature in Cetec ERP, you can enhance visibility, streamline communication, and foster better collaboration among team members. With real-time updates, centralized information, and improved accountability, Production Status empowers your team to work together more efficiently and address challenges proactively.