How to Move an Entire Bin to a Work Order

In manufacturing, picking parts is the process of allocating, or moving, components and raw materials to an active work order. Many times, a warehouse worker simply counts the number of components from a location in the warehouse, or ‘bin’, and picks the exact amount needed to fulfill the job. This is crucial for both inventory control and accurate work in process (WIP) reporting.

What happens when you have to allocate the full bin quantity to a work order, but only need to partially pick and consume to fulfill that job? This comes up for a number of manufacturing industries, but particularly in electronics manufacturing. Often they will need to move an entire reel (modeled as a bin location) to the production line for a job, even though only a portion of the components on that reel are required.

Typically, this would require you either perform a bin move to show the reel on the floor, or you would need to pick the entire reel. This is either a very manual, error-prone process for a warehouse worker, or over inflates your WIP (work in process) inventory numbers.

Cetec ERP has recently developed a feature to solve this exact problem - taking what would be a 5-click process down to one. This guide is going to explain how to use the ‘Full Bin Pick’ feature to gain inventory control and improve warehouse efficiency.

- First, you will need to enable the ‘Order - Show Full Bin Pick Button’ config setting in your environment. Have an admin user navigate to your config settings page by going to the Admin module, clicking the Config Settings, and then clicking Config Settings again in the dropdown menu. Search “Order - Show Full Bin Pick Button” in the __ field. Input a value of 1 into the field and click ‘Set’. This feature is now active in your environment!

The ‘Order - Show Full Bin Pick Button’ feature allows you to pick the full quantity of that bin to that specific work order and have that workorder ‘occupy’ that specific bin you’ve selected.

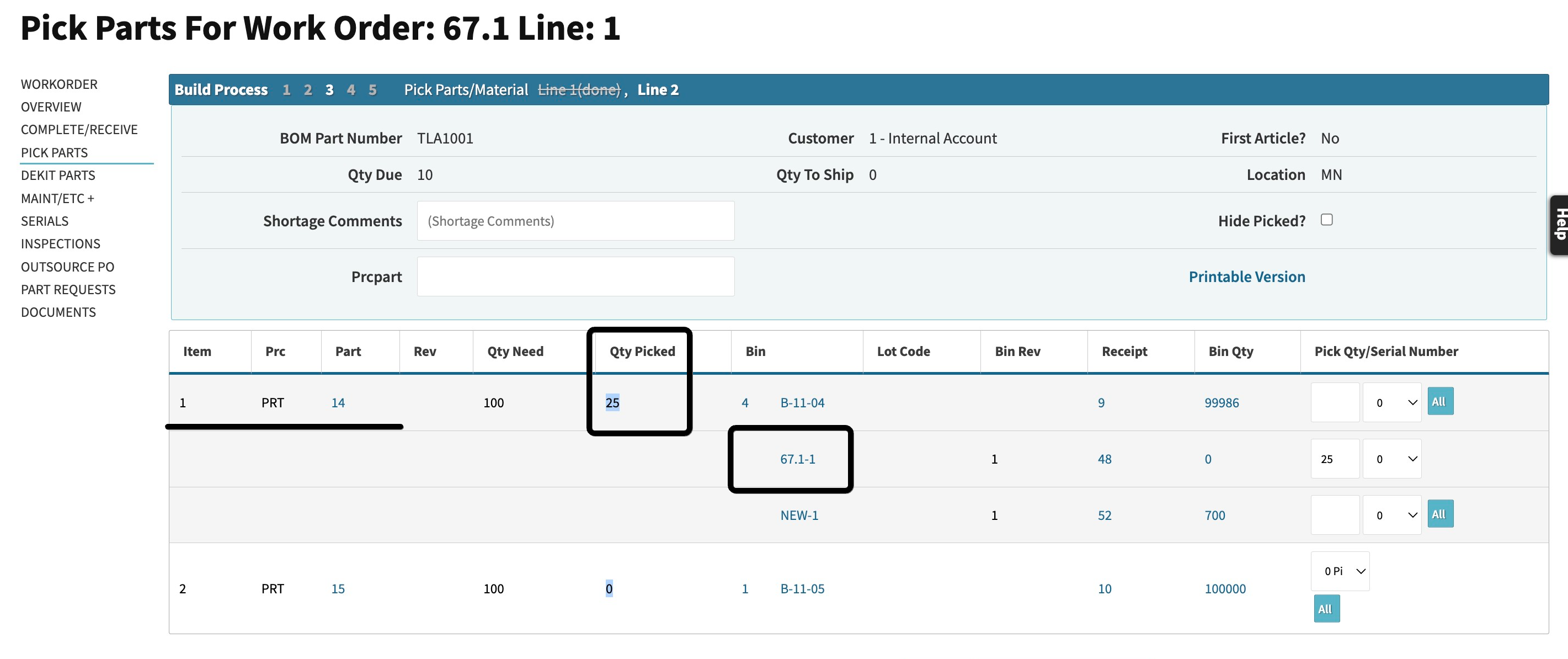

- When you are on the Pick Parts screen for a work order, you will now see a blue ‘All’ button on the far right. Clicking this button on the pick parts screen for a specific bin will pick that entire bin, and rename the bin to the work order number to show you that bin is now picked to that specific work order.

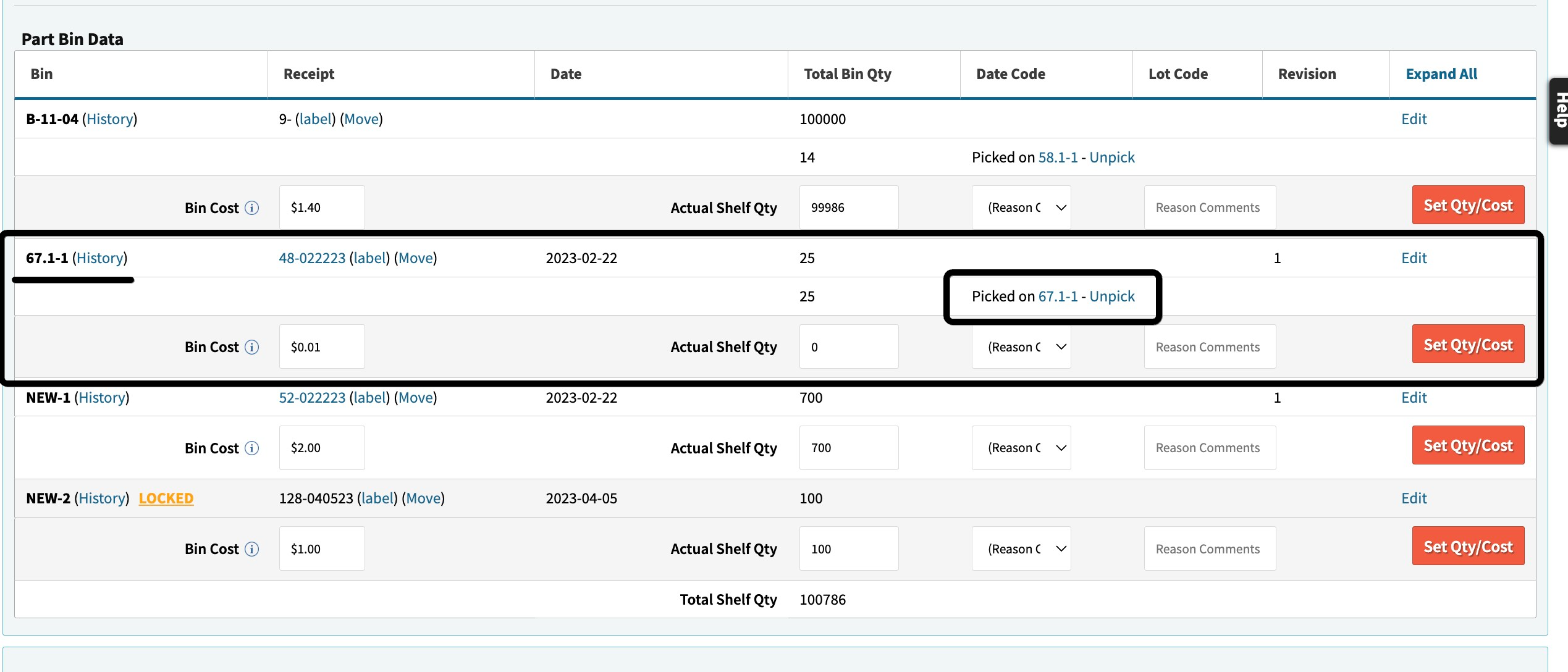

On the second row for part PRT14, I selected the blue ‘All’ button (it’s been selected so no longer shows as an option) and decided to pick all 25 of PRT14 to work order 67.1 Line 1. This picks the quantity required on the work order and moves the entire bin quantity into a bin named 67.1-1. Then, when you go to the part record, you will see that bin allocated to the work order.

This feature is extremely helpful when you need to relocate the full stock of a bin to the production floor for a work order that’s going to consume that stock or material. Using this feature allows you to navigate to the pick list, rename the bin, and relocate that material to the floor in one button press!